Microphone size matters

In any measurement scenario, the measurement equipment and the measurement environment interact in two ways. The first and simplest way is how the microphone ‘adds’ data to the environment, and the second is how the microphone ‘extracts’ data from the environment. And size has a great impact in both directions.

How does the microphone impact the measurement environment?

Like the classic grade-school example of tossing a stone into a pond, any physical object in an acoustic environment will disturb the propagation of waves and therefore influence the sound pressure. This would also include secondary and tertiary objects. In the pond scenario objects like a twig or leaf deflecting or dampening the waves would cause new permeations of the original wave. And in the same way, when performing a measurement trying to get accurate, valid data, the measurement microphones themselves influence the sound pressure in the acoustic environment because they, too, are physical objects with various sizes and shapes.

How does the environment impact the measurement microphone?

This influence, which depends on the type of sound field, is accounted for in each microphone’s design. The microphone responses are optimized to compensate for the measurement environment’s influence. So, if the microphone is used in the intended sound field, it will provide a flat response… up to a point.

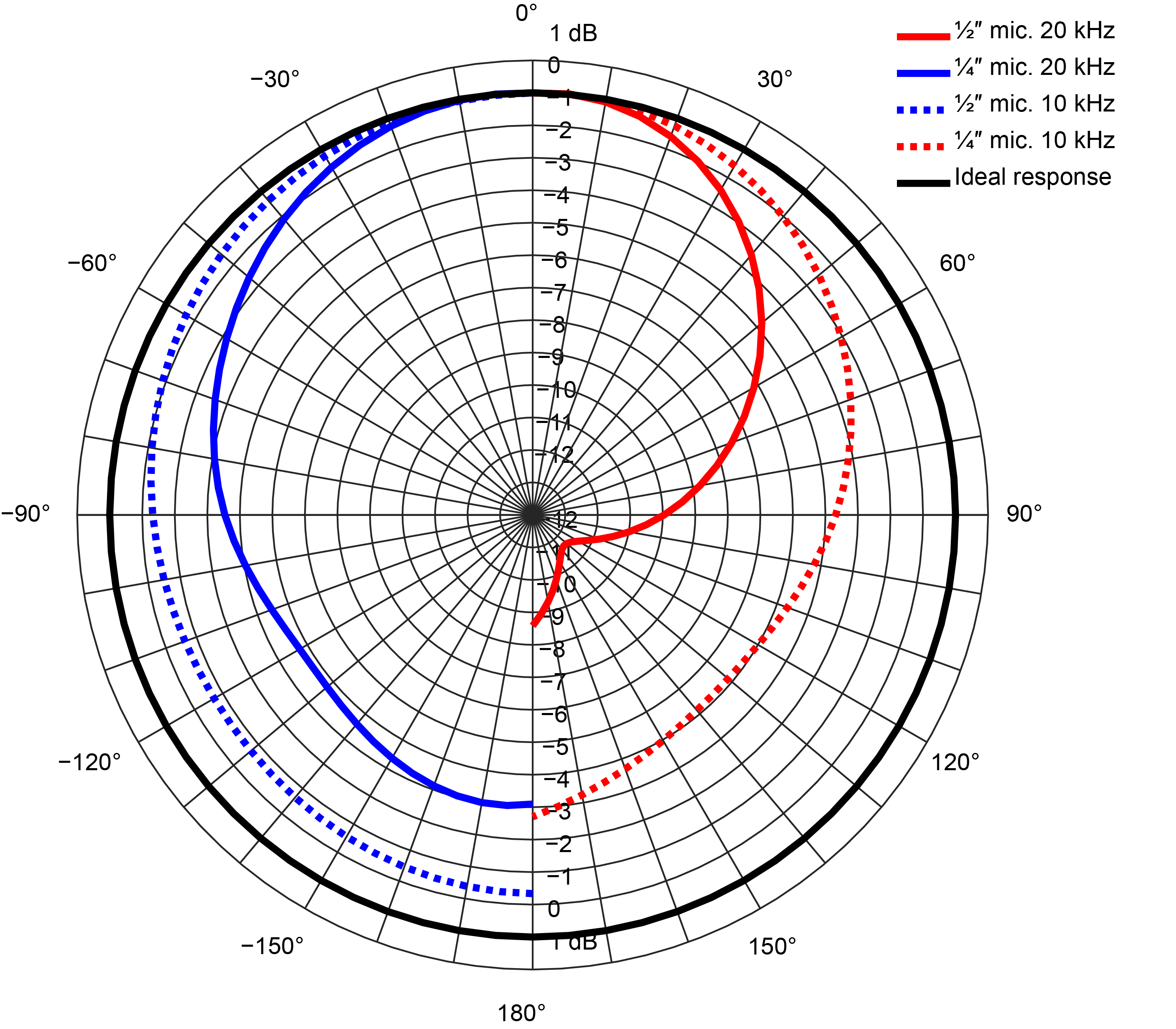

But these design considerations are only valid within a perfect sound field, and using a free-field microphone as an example, even if the measurement is made in a truly reflection-free environment, any free-field microphone will underrepresent sound waves that are not arriving directly perpendicular to the microphone membrane. To make matters worse, this effect is amplified by increasing the physical size of the microphone membrane.

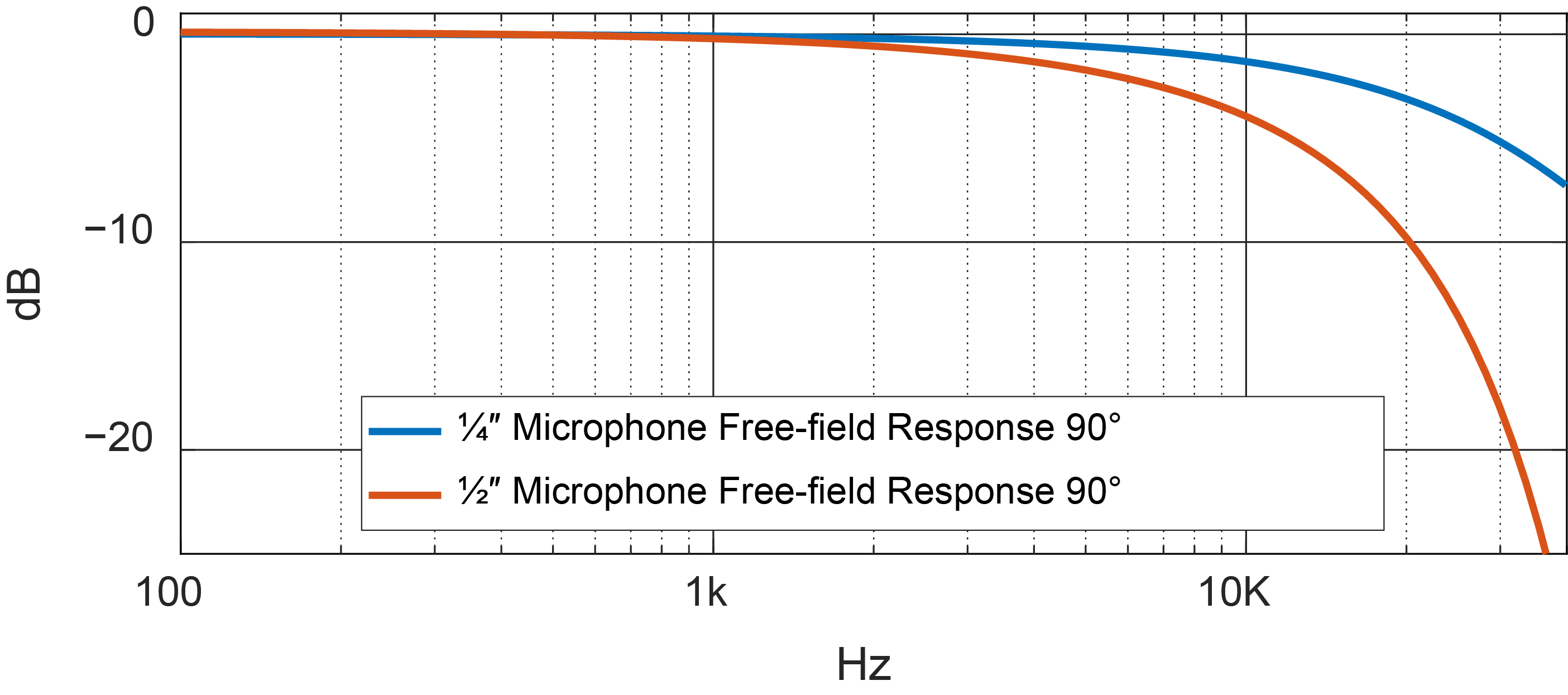

At low frequencies, the underrepresentation is negligible, but by about 2 kHz, it can already be readily observed. However, significant divergence really begins at around 10 kHz. At 20 kHz, a ½″ free-field microphone will underrepresent the sound power of a sound wave at 90° incidence by almost 10 dB; whereas, a ¼″ free-field microphone will only underestimate the sound power by approximately 3 dB.

This means that in a real-life measurement scenario it is always a better idea to measure with a smaller-sized microphone. And on top of the more accurate sound pressure level data, reducing the size of the microphone will reduce reflections and disturbances, providing fewer measurement errors and greater certainty.

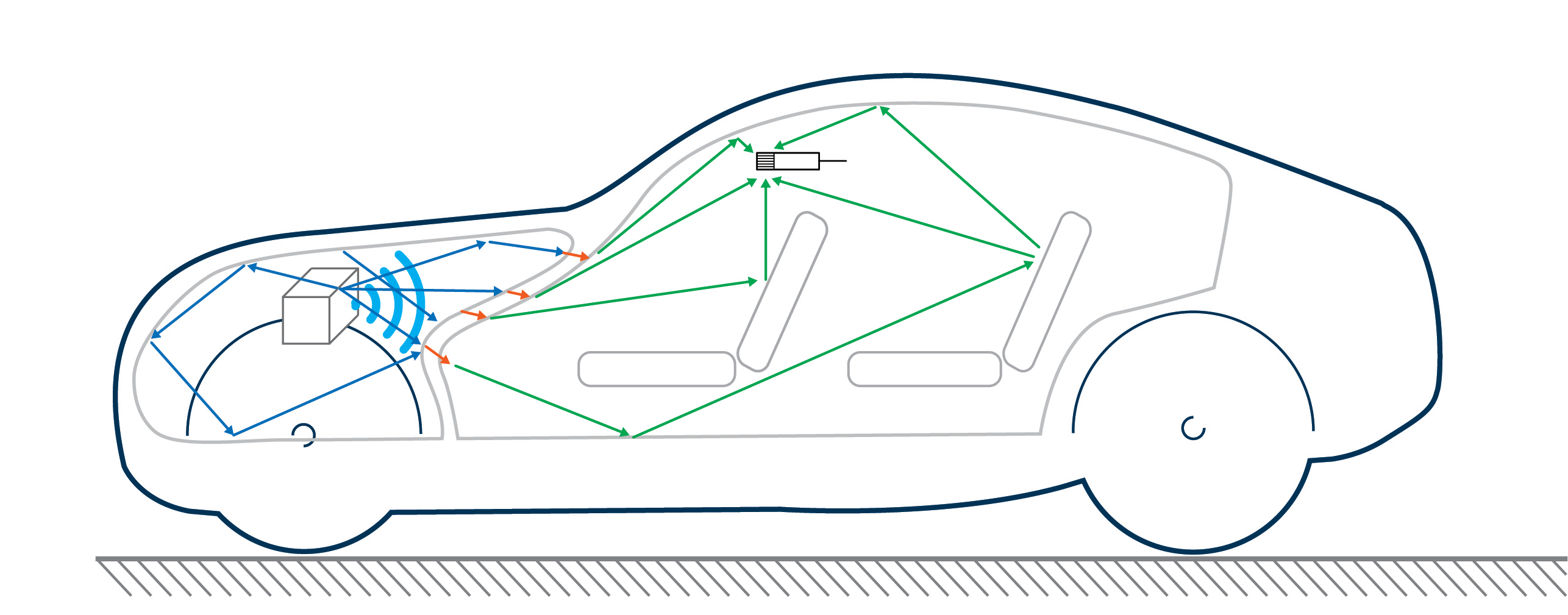

This is particularly critical when sounds are coming from different directions or when multiple sound sources are present. For example, when making in-cabin measurements, where there are many reflections and disturbances, the physical advantages of a ¼″ microphone is an effective way of reducing measurement uncertainty.

However, there is no magic microphone that is perfect for all possible measurement scenarios. Just as smaller diameter microphones have an inherent advantage over their larger brethren at high frequencies, the diaphragms of smaller microphones are less sensitive to small pressure variations than microphones with larger diaphragms. This means that microphones with a smaller diaphragm will be less likely to be used for signals with very low amplitudes.

This is not to say that a ¼″ microphone can, or should, not be used in a lower sound power level measurement scenario. Just as there are ½″ microphones that push the boundaries at higher frequencies, there are also ¼″ microphones that are designed for use at lower sound power levels.

To extend the usefulness of ¼″ microphones, many producers of microphones have spent a lot of time designing low noise ¼″ microphones. Currently while all GRAS ¼″ microphones have the lowest noise floors in the ¼″ range, the GRAS 46BL ¼″ high-sensitivity microphone set claims the title of “industry best” noise floor, which at 25 dB(A), is less than 10 dB higher than a typical ½″ microphone.

The difference between other ¼″ microphones and the 46BL is readily apparent.

Noise @ 45 dB

<audio src="Blog/HP_Voice_45_dB.mp3" controls="controls" type="audio/mpeg"></audio>

Noise @ 25 dB

<audio src="Blog/HP_Voice_25dB.mp3" controls="controls" type="audio/mpeg"></audio>

Want to know more about this topic ?

Download our whitepaper "On the advantages of using 1/4" measurement microphones to reduce uncertainty" where we explain how the size of microphones can affect a measurement and how a microphone diaphragm reacts to incoming signals based on diaphragm size and angles of incidence.